there are different types of errors in energy meter as given above :

- phase error

- friction error

- speed error

- creeping error

- temperature error

- frequency error

- overload error

the energy meter only reads correctly when the shunt magnetic flux lags the applied voltage by exactly 90 degree

In practical manner the pressure coil circuit in energy meter is not purely inductive there are some resistance across the pressure coil circuit.hence the current taken by pressure coil does not lag the applied voltage across the pressure coil by exactly 90 degree

this error is found in energy meter and is known as phase error

by the cause of this error energy meter measure the inaccurate measurments it is not eligible to measure accurately at all the power factors to reduce this error some adjustments are done in energy meter to increase the inductance of pressure coil circuit it is placed on the central limb of the shunt magnet core

to adjust the error more efficiently further a copper shading band is placed on the central limb of the core of shunt magnet by moving the copper shading band along the limb the inductance of the pressure coil can be increased

the inductance is adjusted to such a value that the circuit becomes purely inductive

2.friction error

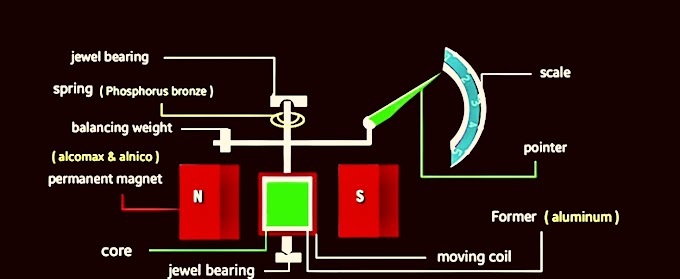

driving torque is a very important in energy meter this driving torque is opposes by the frictional torque is developed when the aluminium disc rotates there is friction at the spindle bearing and the registering mechanism.

this error makes serious impact to light loads.it is necessary to arrange for a small torque whose value is independent of the load on the meter and whose direction is same as that of the driving torque.to remove the error from the device magnitude of this additional torque should be equal to the excess frictional torque.

this is usually obtained by a small shading loop placed between the central limp of the shunt magnet and the aluminium disc slightly the one side of the central limp of the shunt magnet.

the interaction between the portion of the flux which are shaded and unshaded by this loop currents get induced in the aluminum disc due to this current get induced in the aluminium disc

3.speed error

speed of the disc is sometimes high and low due to this discontinuous speed their is error in the final record values of the energy meter this error is known as the speed error.

this error is reduced with the help of brake magnet

if the speed of the disc is increase by the rated speed the brake magnet is moved away from the spindle this increases the braking torque value for reducing the speed

on the other hand if the speed of the disc is less than the rated speed the brake magnet is moved toward the spindle this reduces the braking torque value for increasing the speed

4.creeping error.

the disc of the energy meter makes slow but continuous rotation when only the pressure coil is excited but there is no current flowing through the load or through the current coil due to excessive voltage across the pressure coil and incorrect frictional compensation this is called as creeping error.

due to this creeping error energy meter records the readings when the meter is not working or off

to overcome this error two holes are made in the aluminium disc in opposite direction about the spindle due to this rotation of aluminium disc is limited to maximum half a revolution the disc stop rotating when one of the holes comes under any one pole of the shunt magnet

the creeping of energy meter can be stopped by connecting iron wire or iron piece on the aluminium disc the brake magnet is a permanent magnet hence it will attract the iron piece making the disc stationary.

5.temperature error

as we know the resistance of metals are increased when temperature is increased this causes resistance of metallic part in the device is increased

- a small decrease in the pressure coil flux, thus resistance of the coil increases this affect the angle between the voltage across the pressure coil and pressure coil current.

- decrease in torque produces by all shading bands. this ill causes increase in the resistance of the eddy current path in the 'aluminium' disc

No comments:

Post a Comment